17

Ahilyabai reportedly also summoned skilled

weavers from Gujarat and today there still are

strong linkages between weaver families in

Maheshwar and Gujarat.

Post Ahilyabai

After Ahilyabai’s reign, the capital of Indore

Princely State shifted to Indore. In that period

Maheshwari sarees were still nine yards long. Nine

yards accommodated the stately Maratha-style of

saree, wrapped around the body, pulled between

the legs, pleated and then draped across the chest,

and finally cascading over the shoulder and down

the back in simmering gossamer elegance.

Such a saree was called a

lugda

in local parlance;

and women amongst the Maratha state royalty,

took pride in the elegant fan of pleated fabric

trailing between their feet as they moved through

pujas or parties, like graceful peacocks.

Prior to Independence in Princely State times,

Maheshwari sarees were of pure cotton: warp and

weft. As Maheshwar held a special place in the

hearts of Indore’s rulers, their Maharajas saw to it

that the finest counts of imported cottons came

into their weavers’ hands. So the royal Maheshwari

sarees was often woven with imported Egyptian

cotton threads.

As the Indore of those days was a sovereign

state, there was no restriction on imports. So, at

times, the

jari

, or fine golden threads, used both as

borders and as

butis

, came from Lyon, in France.

In fact, in the late 1970s, I saw an old, old plaque

in a Master Weaver’s office in the Maheshwar

bazaar

read, “Pure golden threads; Lyon” that was

embroidered proudly on a piece of silk, framed

and hung on his wall.

Fine cotton sarees probably changed

to cotton silk sarees sometime in the late fifties or

early sixties. Technical challenges drove the master

weavers of Maheshwar to cease using cotton in

their warps and to substitute it with much stronger,

fine count imported Chinese silk – known locally

as

thani

. This new texture came to be known as

Maheshwari

neem reshmi

sarees. The objective of

discarding the fine cotton warp was a practical

labour-saving idea; but it changed the nature of

Maheshwari sarees forever.

Weavers no longer had to deal with the headache

of sizing (strengthening) a fine cotton warp with a

thick paste of

johar

(sorghum) flour nor would they

need to bother with constantly repairing broken

cotton warp threads because new Chinese silk was

so much stronger. Maheshwar’s weavers could now

earn a bit more money for far less effort and time.

But I personally have always felt that the original

fine pure cotton saree was a more durable and

elegant textile.

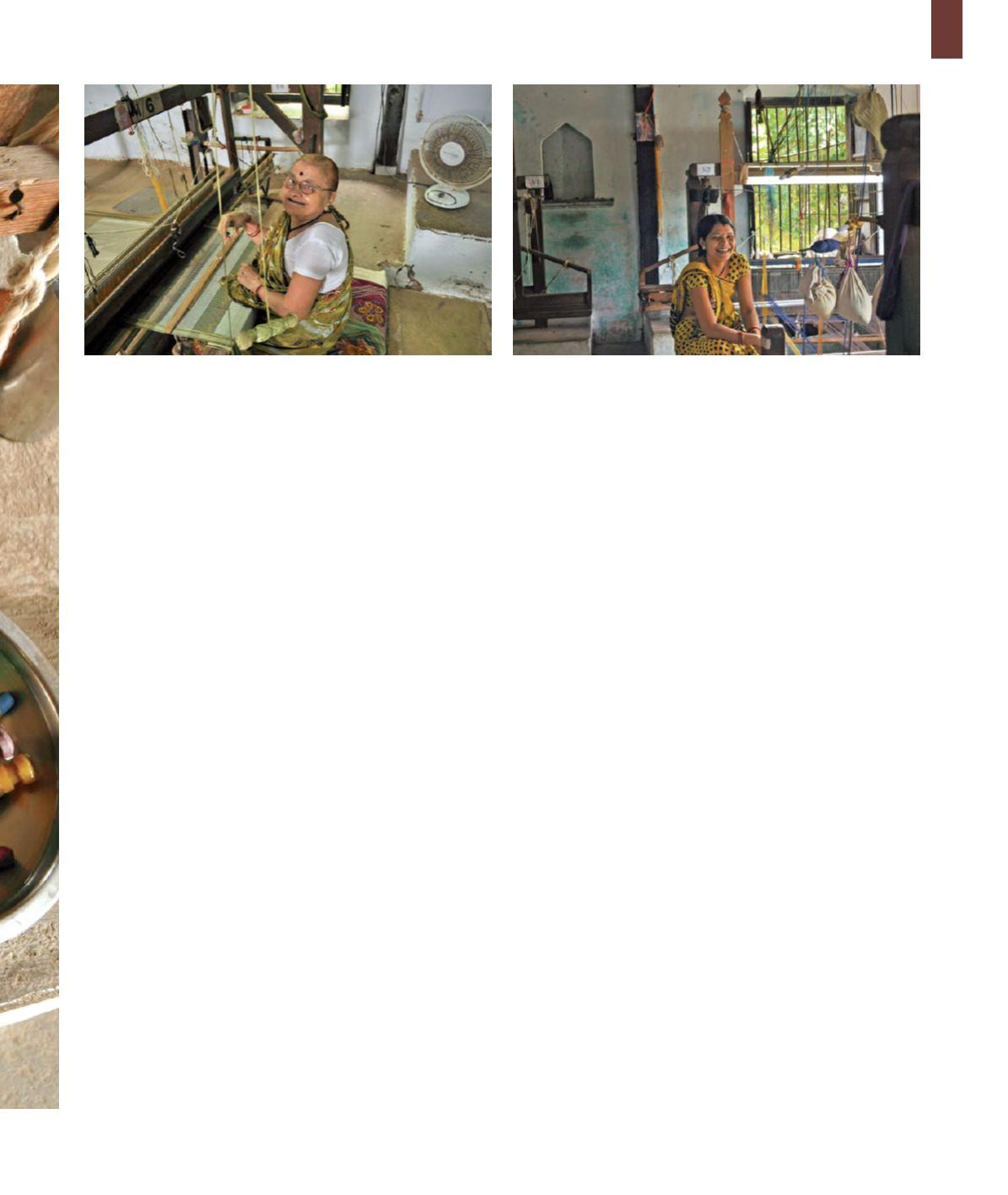

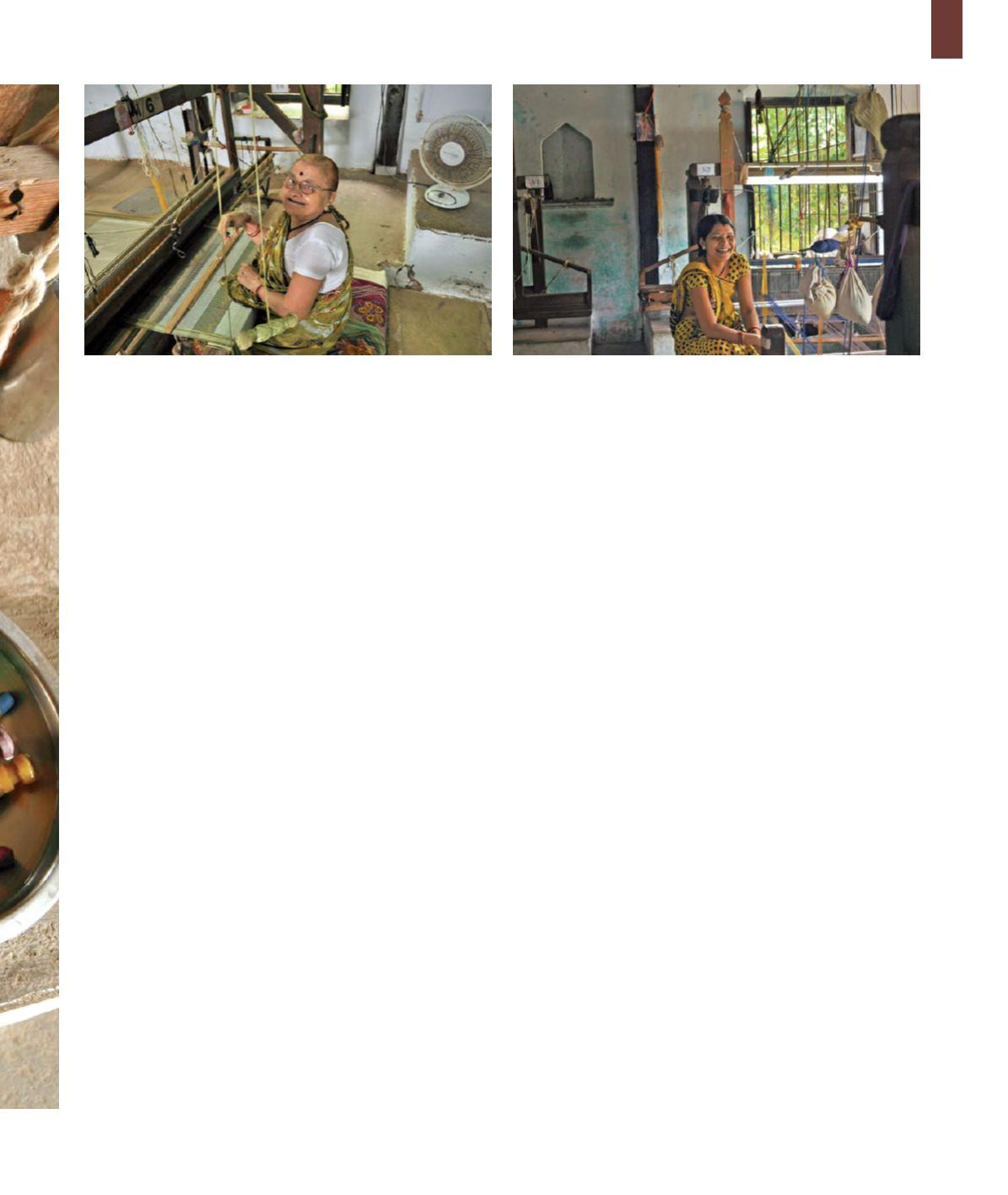

As Maheshwar weaves were relatively simple;

Maheshwar’s looms too have traditionally been

very basic. Their flimsy mud houses and wooden

beams could not support the heavy jacquards

which sat easily in the stone weaver homes of

Chanderi, where the weavers could produce their

elaborate extra warp and weft designs.

Until very recently, Maheshwar looms had only

two treadles, two shafts and very simple dobbies.