35

The Process

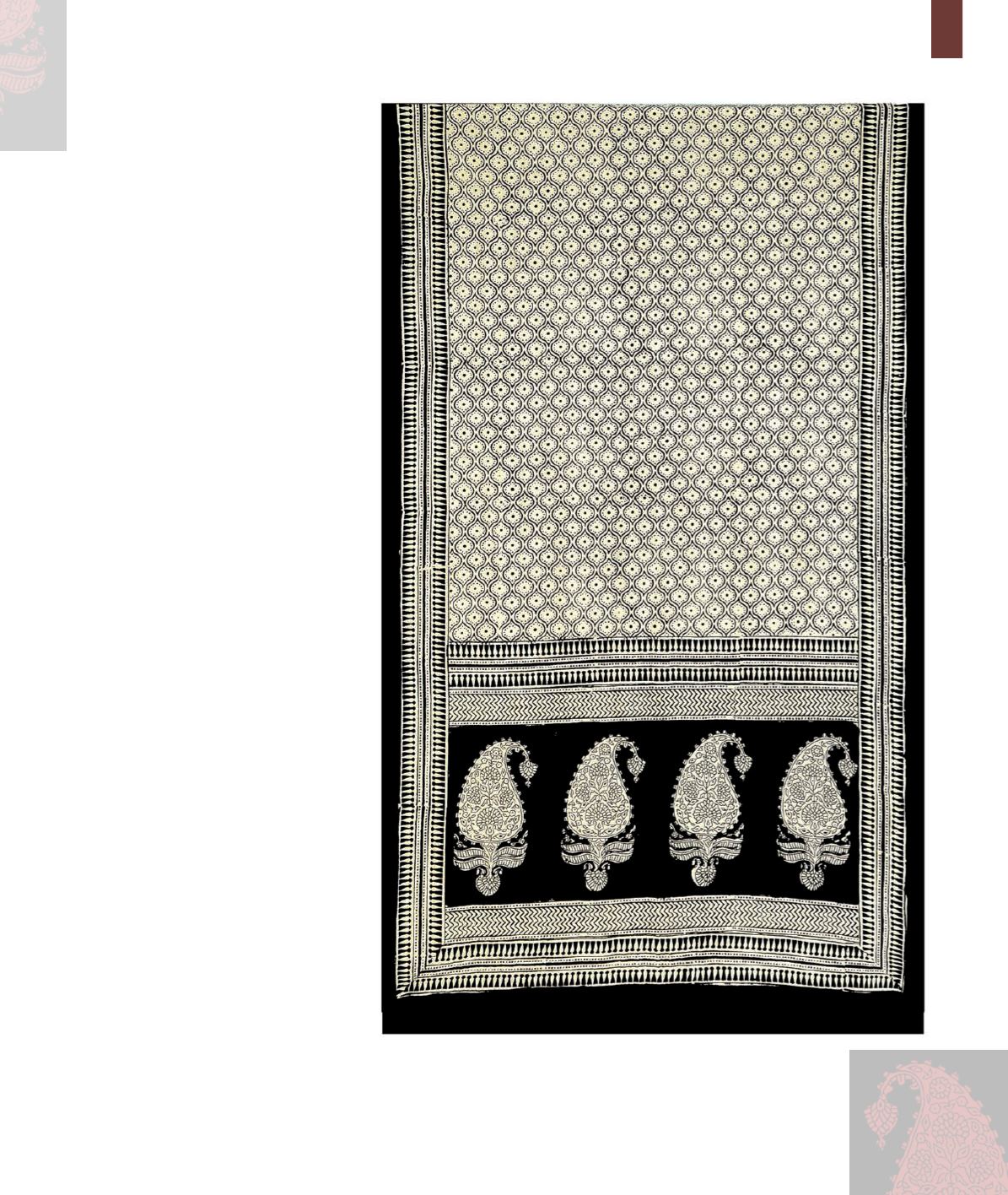

Wooden blocks are carved with motifs

and patterns in relief, and then these

blocks are pressed in a dye to create

motifs within a composition such as a

textile with borders, an end panel and

field. In Bagh, block-printed motifs are

created with red and black coloured dyes.

Most motifs require one block, while

some require two blocks with each block

creating a different part of the motif such

as the outline and the filler.

The block-printing process commences

with the selection of appropriate cloth.

As the process involves boiling the cloth,

it is necessary to work with fabric made

of natural fibres such as cotton, silk and

wool and not synthetic fibres. For stitched

garments, the fabric is cut according to

the garment or home linen to be created

out of it.

The next step involves washing the cloth

and then dipping it in a solution of goat

dung, castor oil and raw salt. This is

important as it removes starch from it

that makes the block-printed motif more

defined and of a deeper colour, and it

also makes the cloth softer. The cloth is

soaked in this solution, then removed and

folded in a very tight bundle and kept on

the ground to allow the cloth to absorb

the solution thoroughly, an action that is

assisted by the heat generated from the

ground below and the solution.

The next day, the cloth bundle is opened

and rinsed at

hodi

, a special place of

the river. It is then beaten on rocks to

remove the starch. It is dipped in the

solution again, and beaten; the process

is repeated three times. This ensures the

starch is removed and the cloth is soft.

The cloth is rinsed and then kept in a tub

filled with a solution of

harad

powder

(Terminalia chebula)

. After squeezing the

cloth, it is dried in the sunlight to obtain

a pale yellow colour. If it is not dried or

treated with

harad

, the colour will not be

obtained.