63

Producing a Telia Rumal requires skill, patience,

time and effort. The white coloured yarns

procured are first soaked for one day in a

solution of goat droppings and water. The

yarns are taken out the next day, dried and then

washed. Then a solution of a powder of the

ash of castor seed pods and sesame oil is made

and the yarns are dipped in it and removed,

every day for twenty-one days. The yarn is then

washed and dried. This oil treatment softens the

yarn, helps it absorb natural dyes and take on

beautiful saturated colours. As mentioned, this

oil treatment of the yarn also gives the textile its

unique properties of keeping the wearer’s head

cool in the summer and warm in the winter, not

sticking to the fisherman’s body when out at sea

and also attracting fish by its smell!

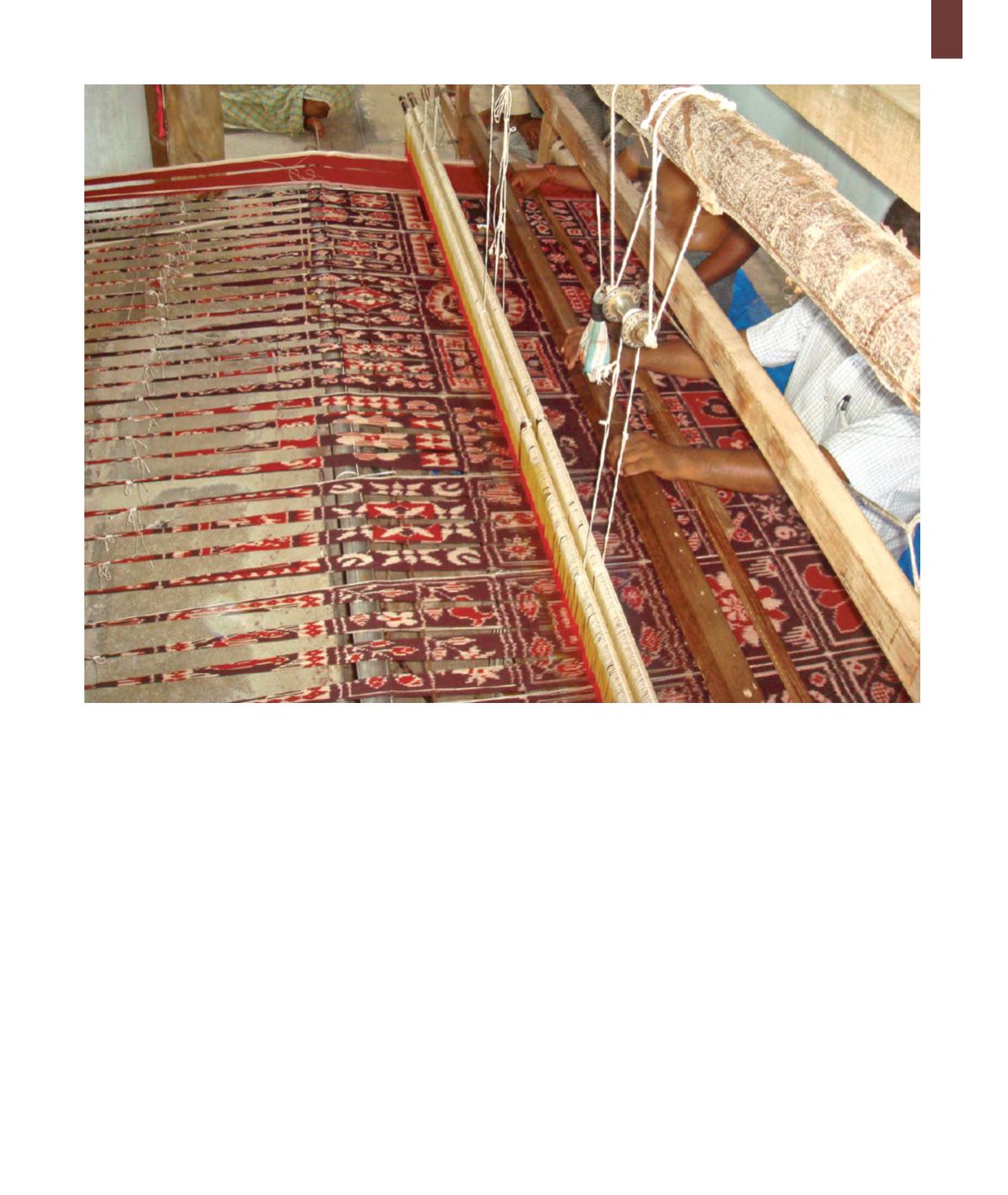

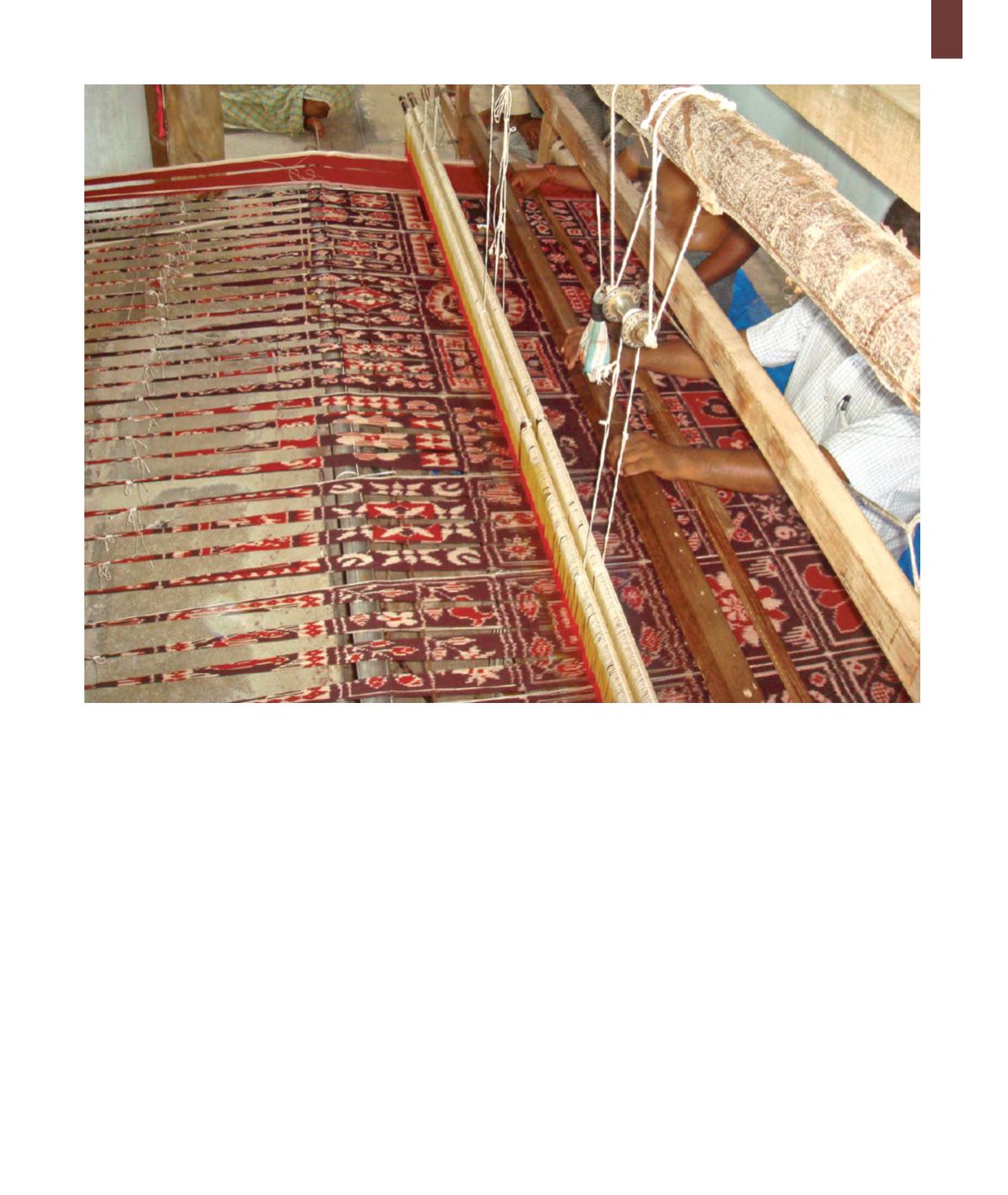

After the yarns are ready for dyeing, they are

tied and dyed that is resist-dyed according to

the pattern decided. The tie-dyeing has to be

perfect so that when the weft and warp yarns

meet at the loom, the weaving will result in

detailed solid colour motifs set in squares or

diamonds. Telia Rumals typically feature a

grid of squares or diamonds or geometrical

patterns. Each square or diamond features a

motif and a broad red border. These motifs

could be of a fruit, flower, bird or animal

or it could be geometric patterns. Some old

Telia Rumals feature motifs like an aeroplane,

wall clock and flower vase! Thus, the dyeing

process required immense concentration to get

the resist-dyed sections right for the complex

patterns. Once the yarns are dyed, they are set